Description:

Induction heating is the process of heating an electrically conductive object (usually a metal) by electromagnetic induction, this is done through the internal generation of heat within the object via the use of Eddy Currents.

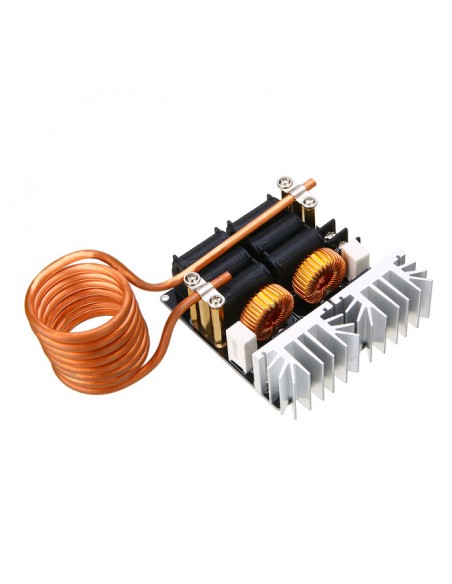

This 1000W Induction heater is a great introduction to small scale induction heating projects. Since its not high powered, it can be used for small DIY parts for hardening, annealing and other heat treatments.

When pairing this up with a graphite or porcelain crucible, It can be used to melt metals such as gold, silver, copper or aluminium. The heating process is really quick and super convenient.

Generally, the higher the voltage you use, the higher the current and better the heating results will be. (MAX. 48V / 1000W)

Specification:

- DC Voltage Supply: 12V - 48V

- Max Current: 20A

- Max Wattage: 1000W

- Inside Coil Diameter: 40mm

- 24V Input no load current: 3A

- 48V input no load current: 6A

- Suitable for a 24V or 36V Power Supply (Not included)

- Suitable Crucible Size: 40mm

Package included:

- 1 x Low voltage 1000W induction heating board

- 1 x Brass coil

Note:

- This unit does not come with any power supplies or cooling units. It is highly recommended that a cooling fan is used against the mainboard oscillators and ends of the copper coil. - If possible, we recommend running coolant through the copper tubing to increase cooling, this will, in turn, increase the heating effectiveness

- If you are using a switch mode power supply. Please make sure that the power supply is on at full 24V/36V before connecting it to the heater. Switch mode power supplies can have a slow start up period whereby the output is not immediately at full voltage. As the voltage ramps up, the induction heater can often turn on at a lower voltage than it should and engages the oscillators out of sequence. Therefore when the voltage is full, the oscillators are not firing correctly will cause the board to burn or not operate properly. Always wait for the power supply to reach its full voltage before connecting the induction heater.

- The volume of the object being heated inside the heating coil should not exceed 1/5 of the volume of the heating coil, this may cause an overload on the induction heater board.

- Although this circuit can tolerate 20-30A input current, It is safer to stick to a max of 15A. It is recommended to monitor your current with an ammeter

- There are 4 x M4 Metal Stand Offs for Fan Mounts.

Note: When using at full wattage it's important to water cool the coil, using a fishtank water pump with reservoir should be fine but using it for prolonged period of time without water cooling will damage the unit!